Windchill FMEA

PTC Windchill FMEA (formerly Relex FMEA)

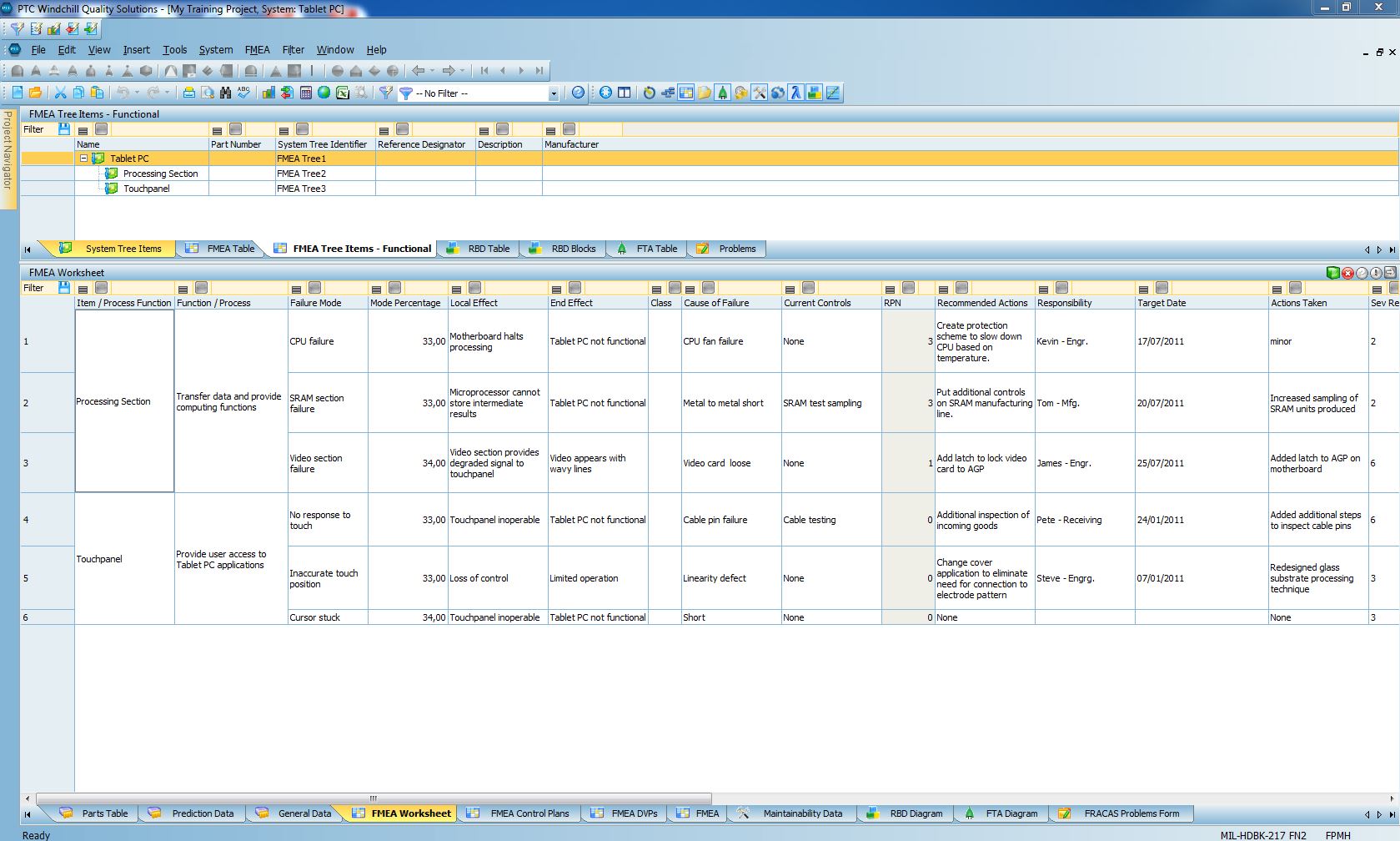

helps organizations improve product quality by identifying the sources and effects of risks and introducing control measures to mitigate or eliminate them. By implementing an FMEA tool early in the product development process, organizations can systematically identify risks at the functional, design, component, or process level and implement risk controls to effectively address them.

PTC Windchill FMEA is a failure mode and effects analysis tool that gives you the power to systematically identify the potential failure modes of a system and control or prevent their occurrence or effects. Supporting a wide range of industry standards used in FMEA and FMECA (Failure Mode. Effects, and Criticality Analysis) risk management techniques, PTC Windchill FMEA enables you to identify and categorize failures, and to develop, organize and implement a plan to address them.

Cross-functional Communication. Leverage built-in DVP&R (Design Verification Plan and Report) and Control Plans to support the cross-functional communication and collaboration integral to successful risk management. Link design verification plans to the FMEA to associate testing procedures directly to failure mode casues. Control plans can be linked directly to the Process FMEA to record, communicate, and implement risk control measures with manufacturing.

Efficient Data Entry. Windchill FMEA supports a range of features that allow you to enter data both efficiently and consistently. Easily import from or export to commonly used formats like Microsoft Excel, Microsoft Access, XML, and plain text files. Assembly libraries provide the ability to reuse approved analyses completed on other projects. Fault Equivalence functionality allows grouping of like failure modes and consequences to ensure consistent risk ranking. Automatically roll up local effects to the failure mode of the next higher level item, and automatically build – or cascade down – the next effect, end effect, and severity to lower level items to ensure traceability. Windchill FMEA also provides industry standard failure modes libraries for component level analyses.

Professional Outputs. Windchill FMEA is supplied with a range of industry standard reports and graphs. Easy-to-use Report and Graph Wizards provide complete user customization of outputs to fit your specific needs, without the need for IT experts. Once complete, reports and graphs can be printed or saved directly to Microsoft Word or Excel, and Adobe PDF.

Enterprise Capabilities. For large scale or distributed deployments, the powerful features of Windchill FMEA are also available in a zero-client, web-based interface with role based permissions, audit capabilities, automated workflow and dashboards. Support for both Microsoft SQL Server and Oracle, with an API for customizable data connectors, enables improved integration with existing business systems.

Technical Highlights

Supported FMEA Types

|

Supported Standards

|

Supported Calculations

|

Dynamic Data Links

|

Download the Windchill FMEA Data Sheet